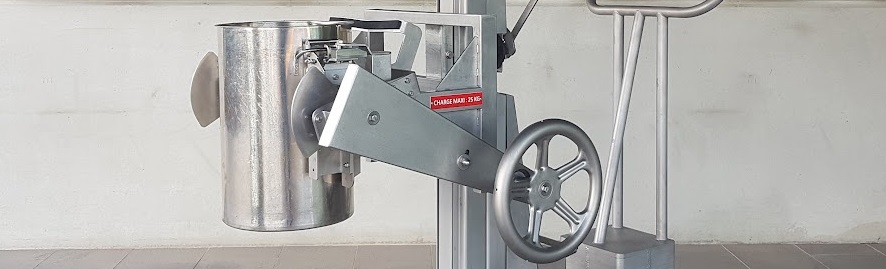

Assisted Handling of Industrial Canisters

Trolley helps in moving and dumping cans

For an industry located in Grasse, ASM has developed an innovative trolley intended to facilitate the movement and dumping of cans. Designed with particular attention to ergonomics, this trolley aims to reduce the risk of musculoskeletal disorders for operators. Its intuitive use, notably thanks to the cranks allowing the cans to be easily lifted and tilted, makes it a valuable tool for improving efficiency and safety in the workplace.

This trolley is a practical and effective solution for industries seeking to improve the working conditions of their employees while increasing their operational efficiency.

Technical description

- Raising/lowering mechanism: worm screw driven by crank (125 mm / revolution maximum)

- 2 rear braked pivoting handling wheels

- 2 lowered swivel castors Ø 60 mm at the front, height on side rails 90 mm / ground

- Capacity given for a load at 400 mm from the mast

- Maximum load: 50 kg

- Min/max lift height: 150 / 1,700 mm (with standard platform)

- Dimensions LxWxH: 570 x 1,047 x 2,000 mm (excluding bottle holder tool)

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- Robotization in the food industry

- Packaging and unpacking robots

- Conveying weighing and mixing perfumes

- trolley lift