Storage and Automated Tests in ATEX Specimens

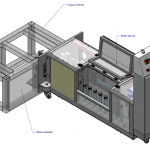

Our Solution for Storage and Testing in Specimens:

Our client, one of the main energy players on the world stage located in the South of France, contacted ASM to design a fully automated machine dedicated to testing petroleum products. Such a product did not exist and until this equipment was produced by ASM, oil manufacturers did not have at their disposal testing equipment dedicated to petroleum-derived products. In direct collaboration with the client's research and development teams, ASM engineers had to take into account numerous requirements linked to the product tested:

- The footprint had to be reduced to a minimum to adapt to the test ovens which were placed on the floor and in a laboratory with little space available

- Versatility of installation, with several sizes of cylinders being used: 25 ml, 50 ml, 100 ml and 250 ml

- Tightness of specimens imposed for the validity of the tests

- Fully automated test management, their duration varying from a few hours to several days

Line features:

After 2000 hours of design and development, ASM has produced a line with the following technical characteristics:

- Testing and storage on a conveyor of 30 hermetically sealed specimens

- Purpose-designed robotic arm, which combines pneumatic cylinders and electric motors

- Maximum miniaturization by integrating the robotic arm in the center of the specimen conveyor

- Versatility of the system dynamically managing different specimen formats

ASM has designed and installed more than 300 production machines. Here are some examples of achievements that might interest you:

- Ultrasonic seizure of solar exchangers

- Remotely operated nuclear dismantling robot

- Nuclear metrology neutrons

- Assisted handling of industrial containers